Are you looking for the highest quality drill presses built specifically with metalworking projects in mind? If so, then it’s time to take a closer look at the best drill presses available on the market today. In this blog post, we review various features and specifications of each of our top-picked drill presses for metalworking projects, as well as their prices so that you can make an informed decision when it comes to purchasing your next piece of equipment. Regardless of what hobby or professional needs you have – from DIY projects to industrial work – don’t miss out on learning more about these impressive pieces of machinery.

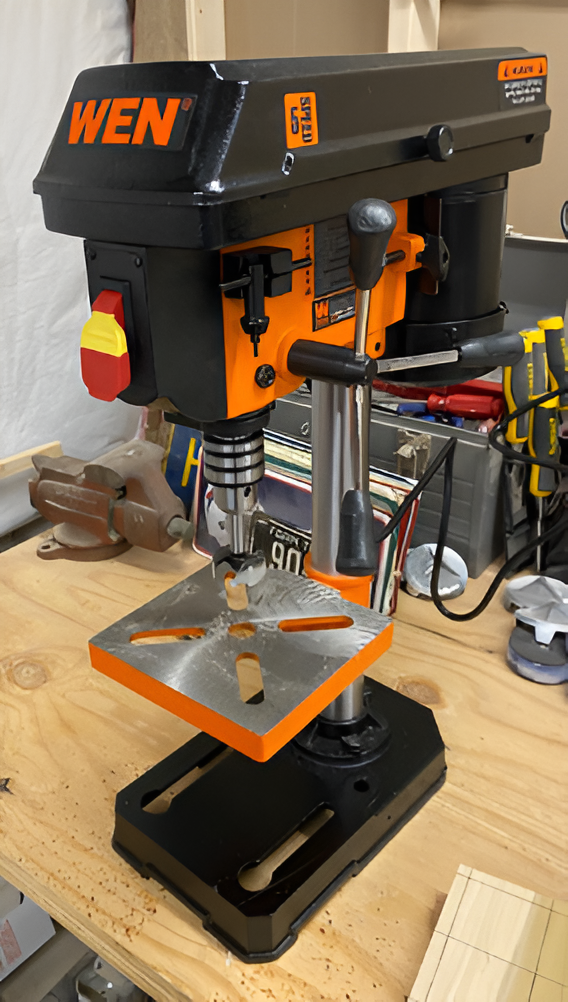

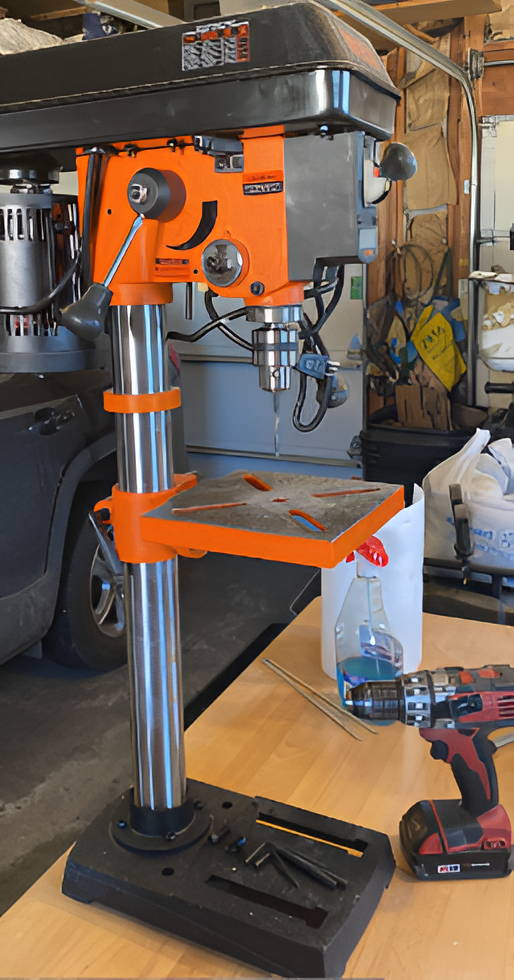

1. WEN 4208T 2.3-Amp 8-Inch 5-Speed Cast Iron Benchtop Drill Press

The WEN 4208T 2.3-Amp 8-Inch 5-Speed Cast Iron Benchtop Drill Press is a compact yet powerful tool designed for precise and versatile drilling tasks. With a powerful 2.3-Amp motor, it offers five speeds ranging from 740 to 3140 RPM. The machine features a sturdy cast iron construction, an adjustable depth stop for repeatable drilling, and a beveling worktable that moves up to 45 degrees for angled drilling. Despite its robust performance, its benchtop design ensures it fits comfortably in small workshops or garages.

The Features Of WEN 4208T 2.3-Amp 8-Inch 5-Speed Cast Iron Benchtop Drill Press

– Powerful 2.3-Amp Motor: The drill press comes with a robust motor that can handle various types of materials.

– Five Operational Speeds: This feature allows you to adjust the drill speed according to your task requirements. The speeds range from 740 to 3140 RPM.

– Compact and Benchtop Design: Despite its powerful capabilities, the drill press boasts a compact design that can fit comfortably on your workbench.

– Durable Cast Iron Construction: The main components of this drill press, including its frame, are made from durable cast iron.

– Adjustable Depth Stop: This feature allows for precise and repeatable drilling operations.

– Spindle Travel & Swing: The WEN 4208T has a 2-inch spindle travel and an 8-inch swing, giving you ample space for various drilling tasks.

– Beveling Worktable: The worktable of this drill press can bevel up to 45 degrees left and right, enabling you to perform angled drilling on your workpiece.

– Onboard Key Storage: For convenience and safety, the WEN 4208T includes onboard key storage to ensure the chuck key is always within reach.

The Pros And Cons Of WEN 4208T 2.3-Amp 8-Inch 5-Speed Cast Iron Benchtop Drill Press

The Pros:

– Powerful Motor: The drill press features a 2.3A induction motor that can handle various materials with ease.

– Accurate Drilling: The rigid frame comprising of cast iron in the head, table, and base ensures accurate holes.

– Versatility: It operates at five different speeds, which gives it the flexibility to handle different types of drilling tasks.

– Convenient Features: Includes a 1/2-inch keyed chuck and onboard key storage for easy accessibility and convenience.

The Cons

– Quality Control: Some users have reported quality control issues with the drill press.

2. SKIL 6.2 Amp 10 In. 5-Speed Benchtop Drill Press

The SKIL 6.2 Amp 10-Inch 5-Speed Benchtop Drill Press is a powerful, versatile tool designed to handle a range of drilling tasks. Its strong 6.2 Amp motor and five operational speeds (570 – 3,050 RPM) provide the power and flexibility to drill through a variety of materials.

This benchtop drill press features an adjustable depth stop for precise measurements and repetitive drilling, and it has a 0-45 degree tilting square work surface for accurate drilling at various angles. The 10-inch swing and 2.5 inches of spindle travel accommodate larger pieces of material.

For added convenience, the SKIL 6.2 Amp Drill Press features onboard storage for chuck keys, helping to prevent misplacement. Its X2 2-Beam Laser ensures precise hole alignment, while the depth adjustment system provides easy depth control.

The Features Of SKIL 6.2 Amp 10 In. 5-Speed Benchtop Drill Press

– Powerful Motor: The drill press has a 6.2 Amp motor, which provides ample power for various drilling tasks.

– Five Speed Settings: It boasts five speed settings, allowing you to adjust the drilling speed to suit different types of materials and tasks.

– Adjustable Depth Stop: This feature allows you to set your desired depth for accurate and repetitive drilling.

– Tilting Work Surface: The work surface can tilt from 0 to 45 degrees, enabling you to drill at various angles.

– X2 2-Beam Laser: This laser guide ensures precise hole alignment, helping to increase accuracy.

– Depth Adjustment System: This system makes it easy to control drilling depth.

– Onboard Chuck Key Storage: This convenient feature helps prevent the loss or misplacement of chuck keys.

– Large Drilling Capacity: With a 10-inch swing and 2.5 inches of spindle travel, this drill press can accommodate larger pieces of material.

The Pros And Cons Of SKIL 6.2 Amp 10 In. 5-Speed Benchtop Drill Press

The Pros:

– Powerful Motor: The 6.2 Amp motor provides ample power for drilling through wood, metal, and other materials.

– Versatile Speed System: The drill press offers five speeds from 610 to 2800 RPM, allowing it to handle different material types.

– Adjustable Features: The adjustable depth stop and table height provide accurate depth during drilling.

– Good Value for Money: It offers a solid feature set and ample power at a price that’s drastically more affordable than Pro-level alternatives.

– Reliability: The benchtop drill press is well built and reliable from an operational standpoint.

The Cons:

– Table Crank Mounting: One major drawback mentioned by a user is the poor mounting of the table crank.

3. VEVOR Mag Drill Press, 2922lbf Power Magnetic Drill with Twist Drill Chuck

The VEVOR Mag Drill Press is a high-powered magnetic drill that offers exceptional drilling performance. It features a powerful 1300W motor, generating a force of 2922lbf, capable of drilling into the toughest materials.

This drill press has a boring diameter of 1.6 inches and can drill up to 2 inches deep, making it suitable for a variety of industrial applications. The package also includes 11 drill bits to cater to your various boring needs.

One of its distinguishing features is the robust electromagnetic base, which solidly anchors the drill press in place, preventing movement during the drilling process5. It also offers adjustable speed gears, ensuring accurate and efficient drilling. The VEVOR Mag Drill Press is not only powerful but also portable, making it a reliable tool for both onsite and offsite jobs.

The Features Of VEVOR Mag Drill Press, 2922lbf Power Magnetic Drill with Twist Drill Chuck

– Powerful Motor: With a 1300W motor, this drill press can generate a force of 2922lbf, making it capable of drilling into tough materials.

– Large Drilling Capacity: The drill press can bore a hole with a diameter of 1.6 inches up to a depth of 2 inches.

– Electromagnetic Base: This feature provides a solid anchor for the drill press, ensuring it stays in place during operation.

– Adjustable Speed Gears: It offers variable speed options that ensure accurate and efficient drilling.

– Portable Design: Despite its power, the drill press is compact and lightweight.

– Included Drill Bits: The package comes with 11 drill bits, providing you with a range of options for various drilling needs.

– Cooling System: The drill press is equipped with a cooling system that helps to reduce heat and extend the tool’s lifespan.

– Overload Protection: This feature safeguards the motor from damage due to excessive load or overheating.

– Comfortable Handle: The handle is designed for comfort and ease of use, reducing fatigue during long periods of operation.

The Pros And Cons Of VEVOR Mag Drill Press, 2922lbf Power Magnetic Drill with Twist Drill Chuck

The Pros:

– Powerful Motor: With a 1300W motor generating a force of 2922lbf, this drill press can handle tough materials with ease.

– Large Drilling Capacity: The ability to bore holes up to 2 inches deep and 1.6 inches in diameter makes this tool versatile for various industrial applications.

– Compact and Portable: Despite its power, the drill press is lightweight and compact, making it easy to transport for onsite and offsite jobs.

– Electromagnetic Base: The strong electromagnetic base ensures stability during operation.

– Adjustable Speed Gears: Variable speed options allow for accurate and efficient drilling.

The Cons:

– High Price Point: Compared to other models in the market, the VEVOR Mag Drill Press is on the higher end of the price range.

– Complex Operation: Some users have reported that the drill press can be complex to operate, especially for beginners.

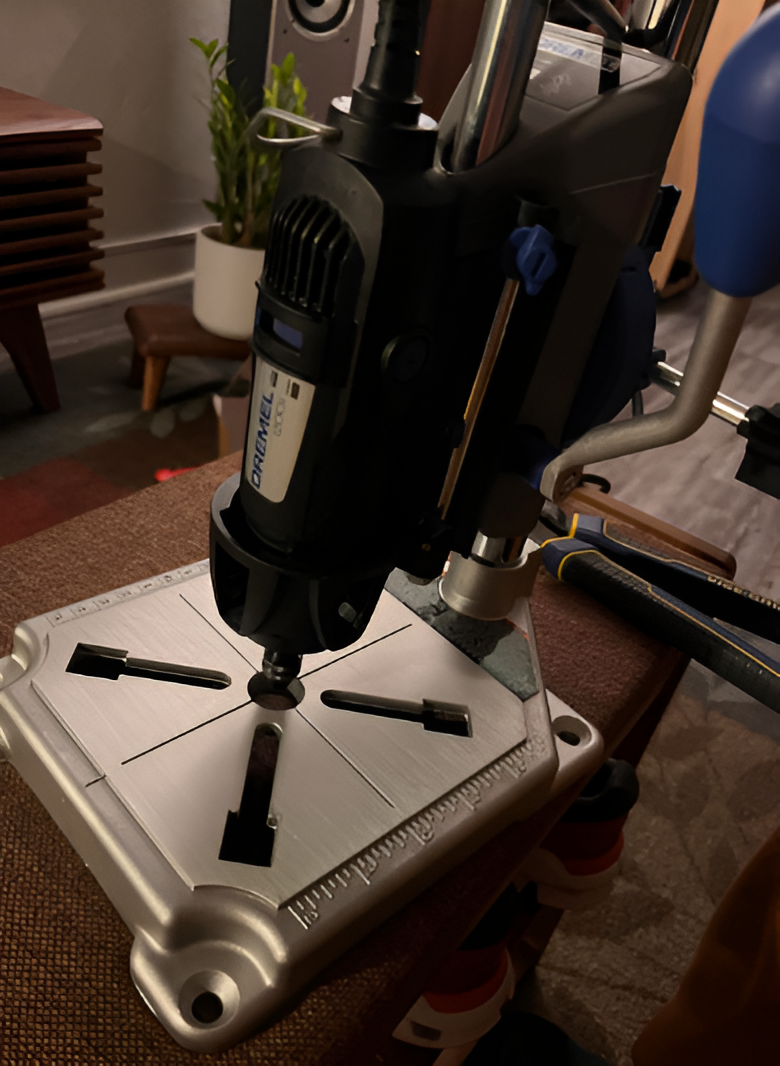

4. Dremel Drill Press Rotary Tool Workstation Stand

The Dremel Drill Press Rotary Tool Workstation Stand is a versatile and flexible stand that can be used for drilling, grinding, sanding, and other functions. It’s designed to hold a Dremel rotary tool, which is not included with the workstation stand.

This workstation stand features a drill press, rotary tool holder, and flex-shaft tool stand in one compact, easy-to-use piece of equipment. With its articulated drill press, it can drill perpendicular and angled holes in 15-degree increments, up to 90 horizontal degrees.

It is built with a sturdy metal base with four clamping points, ensuring secure and stable work on your projects. The workstation also has an integrated, crow’s nest provides onboard storage for drill bits, wrenches, and other Dremel accessories.

The Features Of Dremel Drill Press Rotary Tool Workstation Stand

– Articulating Drill Press: This allows for drilling perpendicular and angled holes in 15-degree increments, up to 90 horizontal degrees.

– Tool Holder: The workstation can hold a variety of Dremel rotary tools, providing a stable platform for precise tasks.

– Flex Shaft Tool Stand: This feature allows for telescopic adjustment to any height between 16 and 29 inches.

– Sturdy Metal Base with Four Clamping Points: These ensure secure attachment to work tables and other surfaces.

– Crow’s Nest Onboard Storage: This provides convenient storage for drill bits, wrenches, and other Dremel accessories.

– Inch and Metric Marking on Base: For accurate drilling of workpiece.

– Depth markings with depth stop: For consistent depth adjustment.

– Cord Management Clips: These help keep power cords out of the way during use.

The Pros And Cons Of Dremel Drill Press Rotary Tool Workstation Stand

The Pros:

– Versatility: The workstation can serve as a drill press, rotary tool holder, and flex-shaft tool stand, making it useful for several applications.

– Articulating Drill Press: It allows for drilling at different angles, offering flexibility in operations.

– Onboard Storage: The crow’s nest provides convenient storage for drill bits, wrenches, and other Dremel accessories.

– Adjustable Height and Depth: This feature makes it adaptable to various project needs.

– Sturdy Construction: The metal base with four clamping points ensures stability during use.

The Cons:

– Limited Compatibility: The workstation is primarily designed for Dremel tools, limiting its compatibility with other brands.

– Setup Difficulty: Some users have reported that the assembly and setup process is complex.

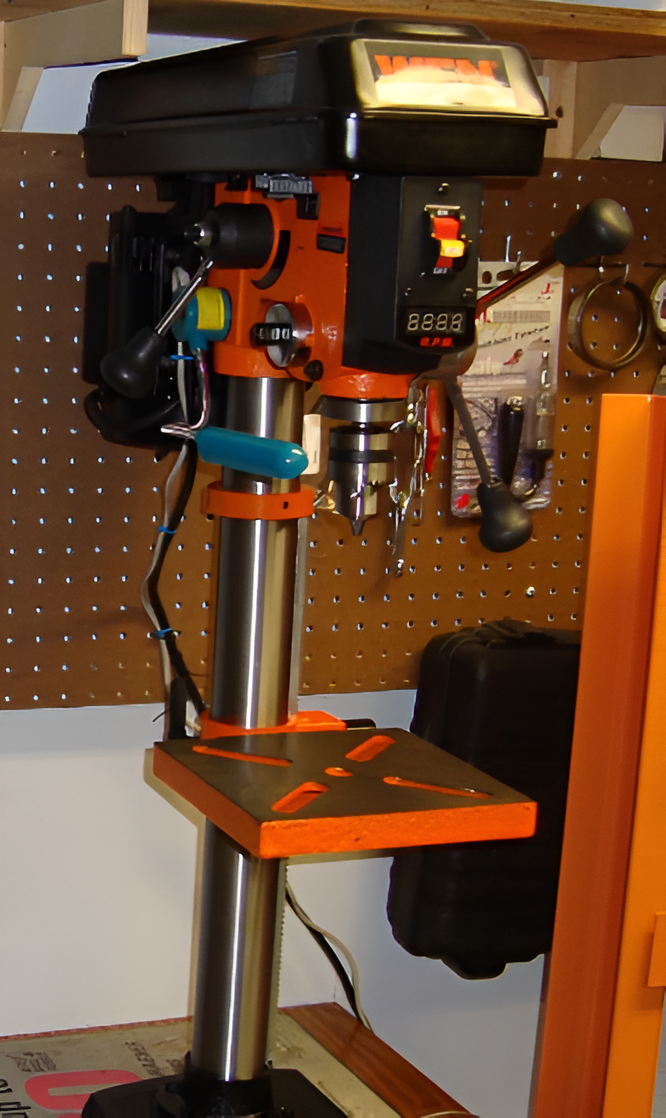

5. WEN 4212T 5-Amp 10-Inch Variable Speed Cast Iron Benchtop Drill Press

The WEN 4212T 5-Amp 10-Inch Variable Speed Cast Iron Benchtop Drill Press is a powerful and versatile tool designed for precision and durability. This benchtop drill press offers a range of features that make it ideal for both hobbyists and professionals.

At the heart of this drill press is a 5-amp motor, capable of delivering variable speeds from 530 to 3100 RPMs, allowing users to choose the best speed for their particular project1. The 10-inch swing and 2-1/2 inch spindle travel make it suitable for a variety of drilling tasks.

Crafted from cast iron, the WEN 4212T ensures stability and minimizes vibrations during operation. The worktable bevels 45 degrees left and right, allowing for angled drilling in both directions.

The Features Of WEN 4212T 5-Amp 10-Inch Variable Speed Cast Iron Benchtop Drill Press

– Variable Speed: The drill press has a variable speed range from 530 to 3100 RPM, allowing users to choose the best speed for their specific project.

– Powerful Motor: It is equipped with a 5-amp motor that provides ample power for different drilling tasks.

– Laser Guide: This feature ensures precise drilling by providing a clear and accurate target.

– LED Readout: The LED screen shows the current speed of the drill press, enabling users to monitor and adjust as necessary.

– Cast Iron Construction: The drill press is made from cast iron, ensuring durability and stability during operation.

– Adjustable Worktable: The worktable can bevel 45 degrees left and right, allowing for angled drilling.

– Spindle Travel: The drill press has a 2-1/2 inch spindle travel for deeper drilling capacity.

The Pros And Cons Of WEN 4212T 5-Amp 10-Inch Variable Speed Cast Iron Benchtop Drill Press

The Pros:

– Variable Speed: The drill press offers a wide range of speeds, which can be easily adjusted depending on the material and type of job.

– Precision: The laser guide and LED readout help ensure precise drilling.

– Durability: The cast iron construction provides stability and durability.

– Versatility: The adjustable worktable allows for angled drilling, making it suitable for a variety of tasks.

– Powerful Motor: The 5-amp motor provides ample power for heavy-duty drilling.

The Cons:

– Assembly: Some users have reported that the assembly instructions could be clearer.

– Belt Adjustment: Changing the speed requires manual adjustment of the belt, which some users have found inconvenient.

What Are The Advantages Of Using A Drill Press For Metalworking?

When it comes to metalworking, using a drill press offers several advantages over handheld drills. Here are some benefits of using a drill press for metalworking:

- Accuracy and Precision: Drill presses provide greater accuracy and precision compared to handheld drills. The fixed position of the drill bit and the ability to adjust the drilling depth and table height allow for consistent and accurate hole placement in metal.

- Variable Speed Control: Many drill presses offer adjustable speed settings, allowing you to match the speed to the hardness of the metal being drilled. This control over speed helps prevent overheating and ensures cleaner and more efficient drilling.

- Depth Stop Feature: Drill presses often come with a depth stop mechanism that allows you to set a specific drilling depth. This feature is particularly useful when you need to create holes of consistent depth in metal, such as when tapping or countersinking.

- Power and Stability: Drill presses are generally more powerful than handheld drills, making them capable of handling tougher metalwork projects. Additionally, the stable base and column of a drill press provide a solid platform for drilling, reducing the risk of wobbling or drifting during the drilling process.

- Larger Workpieces: Drill presses typically have larger worktables and greater clearance between the table and the spindle, allowing you to work with larger and heavier metal pieces more comfortably and securely.

- Versatility: While primarily used for drilling, drill presses can often be equipped with various accessories, such as sanding drums, mortising attachments, and drum sanders, expanding their versatility for different metalworking tasks.

Overall, using a drill press for metalworking offers enhanced precision, control, power, and stability, making it an ideal choice for those seeking accurate and efficient drilling operations.

What Are The Different Types Of Drill Presses Available For Metalworking?

When it comes to drill presses for metalworking, there are several types available. Here are some of the different types of drill presses commonly used in metalworking:

- Benchtop Drill Press: These compact and portable drill presses are designed to be placed on a workbench or table. They are suitable for smaller metalworking projects and offer versatility and precision.

- Floor Drill Press: Floor-standing drill presses feature a larger size and more powerful motor. They are designed for heavy-duty metalworking tasks and provide stability and durability.

- Radial Drill Press: Radial drill presses have a movable arm that can rotate and extend to reach different parts of a large workpiece. This type of drill press is ideal for drilling holes in larger metal objects.

- Magnetic Drill Press: Also known as mag drills, magnetic drill presses use electromagnetic force to secure the drill to the metal surface. They are commonly used in construction and industrial settings for drilling large and precise holes in metal.

It’s important to consider the specific requirements of your metalworking projects and choose a drill press that suits your needs in terms of size, power, and versatility.

How Do I Select The Right Drill Bit For Metal?

When selecting the right drill bit for metal, there are a few factors to consider. Here are some tips to help you choose the best option:

- Material: Different drill bits are designed to work with specific materials. For drilling into metal, consider using cobalt bits, which are known for their hardness and durability.

- Bit Design: Look for drill bits with a 135-degree point or a split point. These designs help to prevent slipping or skating and provide better control while drilling into metal.

- Hardness: Choose a drill bit made of a harder metal, such as high-speed steel (HSS), for drilling into harder metal substrates like stainless steel.

- Length: The length of the drill bit should be appropriate for the thickness of the metal you’re working with. Using a shorter bit for thinner metals can help maintain stability and precision.

What Safety Precautions Should I Take When Using A Drill Press For Metal?

When using a drill press for metal, it’s important to follow safety precautions to protect yourself and ensure safe operation. Here are some safety precautions to consider:

- Wear Safety Gear: Always wear safety glasses or goggles to protect your eyes from metal chips and debris. Avoid wearing loose clothing, ties, gloves, rings, watches, or bracelets that could get caught in the drill press.

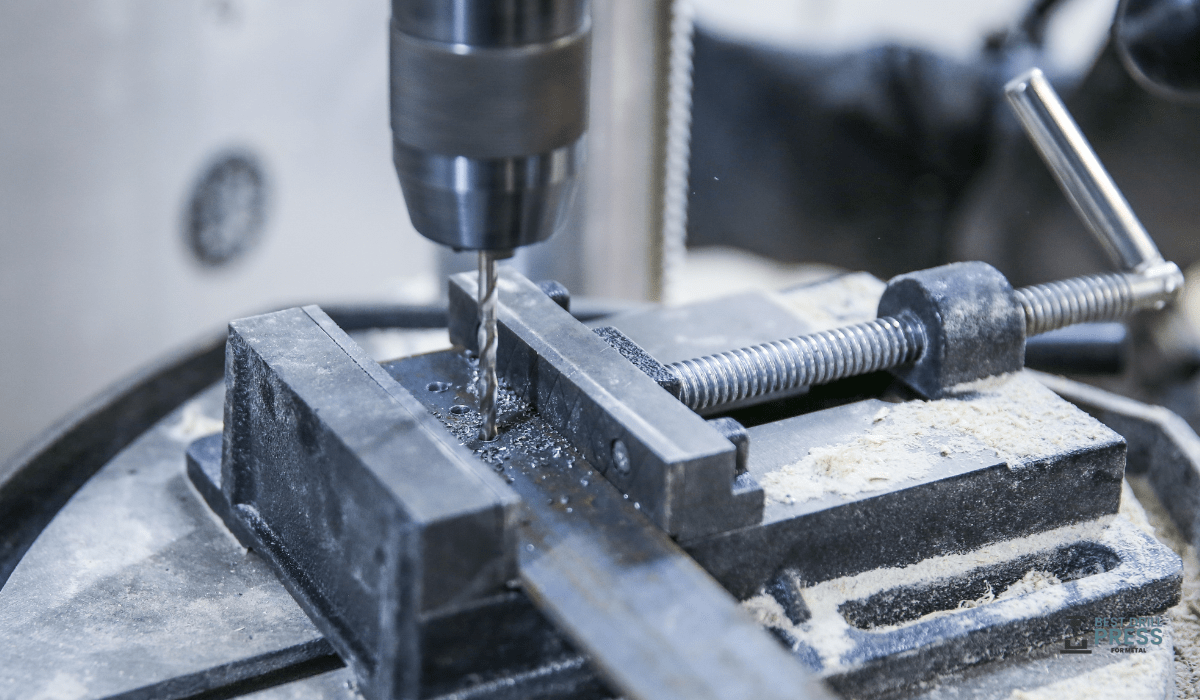

- Secure Workpiece: Properly secure the metal workpiece to be drilled using clamps or a vise to prevent it from spinning or moving during drilling. This ensures stability and reduces the risk of accidents.

- Positioning: Maintain a clear workspace around the drill press. Stand in a comfortable position with a stable stance, keeping your body balanced and away from the moving parts. Avoid reaching across the machine while it is in operation.

- Adjustments: Make all speed adjustments, setting changes, and measurements only when the drill press is completely turned off and at a full stop. Never make adjustments or changes while the machine is running.

- Clear Workspace: Remove any metal chips, debris, or obstructions from the drill press table and surrounding area. Do not attempt to remove chips by hand; use brushes or other tools to properly clean the machine.

- Cutting Fluids: Depending on the material being drilled, you may need to use cutting fluids or lubricants to reduce heat and friction. Follow the manufacturer’s recommendations and guidelines for their safe use.

- Unplug Power: Before making any adjustments, changing drill bits, or performing maintenance, always unplug the power cord or turn off the power source to ensure the drill press cannot accidentally start while you are working on it.

How Do I Maintain And Care For A Drill Press For Metalworking?

Maintaining and caring for a drill press for metalworking is essential to ensure its longevity and optimal performance. Here are some maintenance tips:

- Lubrication: Regularly lubricate the chuck and spindle assembly using a dry lubricant such as WD-40 Specialist® Dry Lube or an appropriate lubricant recommended by the manufacturer. This helps keep the components functioning smoothly.

- Clean and Sharp Drill Bits: Keep the drill bits clean and sharp. Dull drill bits are more prone to breakage and can lead to poor drilling performance. Clean the drill bits after use and sharpen them as needed.

- Clear Work Area: Maintain a clean and clutter-free work area around the drill press. Remove any oil, grease, or debris from the floor to prevent slips and maintain a safe working environment.

- Inspect and Tighten: Regularly inspect the drill press for any loose bolts, screws, or parts. Tighten them as necessary to ensure stability and proper functioning of the machine.

- Clean Surfaces: Clean the column, table, chuck, and other surfaces of the drill press regularly. Use a plastic abrasive pad or steel wool to scrub the surfaces, then wipe them dry with a clean rag.

- Check Drive Belt: Inspect the drive belt periodically for signs of wear or damage. Replace the belt if necessary to maintain proper power transmission.

- Power Source: Check the power source and electrical connections of the drill press. Ensure that the power cord is in good condition and properly grounded for safety.

Tips For Using A Drill Press For Metalworking

Here are some tips for using a drill press for metalworking:

- Choose the Right Drill Bit: Select a high-quality drill bit designed specifically for metal drilling. Carbide or cobalt drill bits are commonly used for drilling through metal.

- Secure Your Workpiece: Ensure that your workpiece is securely clamped or held in place to prevent it from moving or spinning during drilling. This will help maintain accuracy and prevent accidents.

- Use Cutting Fluid: When drilling through metal, it’s recommended to use cutting fluid or lubricant. This helps cool down the drill bit and reduces friction, resulting in smoother and cleaner holes.

- Adjust Speed and Feed Rate: Different types of metals require different drilling speeds. Consult the manufacturer’s guidelines or reference charts to determine the appropriate speed and feed rate for the specific metal you’re working with.

- Mark Your Hole Locations: Before drilling, use a center punch or awl to mark the exact spot where you want to drill. This will help guide the drill bit and prevent it from wandering off-center.

- Start with a Pilot Hole: For larger holes, it’s often a good idea to start with a smaller pilot hole. This helps create a guide for the larger drill bit and improves accuracy.

- Use Proper Technique: Maintain a steady hand and apply even pressure when drilling. Avoid forcing or pushing too hard, as this can cause the drill bit to overheat or break.

- Clear Chips Regularly: Metal chips can accumulate around the drill bit, reducing its effectiveness and causing overheating. Clear the chips regularly by retracting the drill bit and using compressed air or a brush to remove debris.

- Wear Safety Gear: Always wear safety goggles or glasses to protect your eyes from flying debris. Additionally, consider wearing gloves and hearing protection for added safety.

- Clean and Maintain: After each use, clean the drill press and remove any metal shavings or debris. Regularly check and maintain the drill press according to the manufacturer’s guidelines to ensure optimal performance.

FAQs About The Best Drill Presses for Metal

What is a drill press?

A drill press is a stationary power tool used for drilling holes in various materials, including metal. It consists of a motor-driven spindle mounted on a vertical column, with a worktable and adjustable depth settings.

Can I use a regular drill press for metalworking?

Yes, many drill presses are designed for versatile use with different materials, including metal. However, it’s important to ensure the drill press you choose has the appropriate power and features for metalworking tasks.

Can a drill press be used for other tasks besides drilling?

Yes, many drill presses can be equipped with accessories such as sanding drums, mortising attachments, and drum sanders, which expand their functionality for different metalworking tasks.

Can a drill press be used for other materials besides metal?

Yes, a drill press can be used for drilling holes in a variety of materials such as wood, plastic, and composites in addition to metal.

Are there different types of drill presses for metalworking?

Yes, there are various types of drill presses, including benchtop models and floor-standing models. Benchtop drill presses are compact and suitable for smaller projects, while floor-standing models offer more power, stability, and versatility for larger and more demanding tasks.

What Accessories Should I Use With My Drill Press For Metalworking?

When using a drill press for metalworking, several accessories can enhance its functionality and safety. First, drill bits specifically designed for metal, like high-speed steel (HSS) or cobalt drill bits, are essential. Second, a drill press vise can hold your workpiece securely, ensuring accuracy while providing safety. Third, a drill press table with adjustable fences helps in precise hole alignment. Fourth, using cutting fluid can prolong the life of your drill bits and make the drilling process smoother. Lastly, safety gear including eye protection, ear protection, and durable gloves are indispensable for any metalworking project.

How Do I Lubricate My Drill Press For Metalworking?

Lubricating your drill press for metalworking involves a few simple steps. First, turn off and unplug your drill press to ensure safety. Next, clean any debris or old lubricant from the drill press, focusing on areas such as the spindle and the quill. Once clean, apply a light machine oil to these areas. For the spindle, raise it to its highest point and apply a few drops of oil onto the shaft, then lower and raise the spindle a few times to distribute the oil. Similarly, for the quill, extend it fully, apply oil, and then retract and extend the quill a few times. Lastly, wipe off any excess oil with a clean cloth. Following these steps will keep your drill press running smoothly and prolong its life.

How Do I Adjust The Speed On My Drill Press For Metalworking?

Adjusting the speed on your drill press is crucial for efficient and safe metalworking. Start by turning off and unplugging your drill press. The speed is adjusted by changing the arrangement of the drive belts on the pulleys. Open the top cover of your drill press to expose the pulleys and drive belts. They typically feature a stepped-pulley system, with the larger pulleys providing slower speeds, and the smaller ones faster speeds.

For metalworking, lower speeds are generally preferred. To slow down the drill press, move the drive belt to a larger pulley on the spindle side and a smaller pulley on the motor side. Once you’ve adjusted the belts, close the top cover. Always refer to your drill press’s manual for specific speed recommendations for different materials and drill bit sizes. Remember, safety comes first. Always make sure your drill press is off and unplugged when making adjustments

Conclusion

Views on the best drill presses for metal have been presented in this article. From the reviews given, it is clear that each model offers something unique and has different features to offer depending on what you need. Whether you are looking for a heavy duty drill press with digital readouts or a more budget-friendly solution, there is sure to be an option that is right for your shop. All things considered, the final decision will come down to personal preference and budget, which can make finding the perfect fit for your needs quite tricky. Regardless of which model you decide on, make sure to invest in quality and function when choosing a drill press with metal capabilities.